The mechanical engineering sector is one of those areas where the demand for aluminium has increased in recent decades. This growth is due to the physical and chemical properties of this metal alloy.

It is important to understand, therefore, why aluminium plays a primary role in this field, discovering what the main characteristics of this alloy are and how they relate to the various applications in the mechanical field.

MAIN MECHANICAL PROPERTIES OF ALUMINIUM

Aluminium is a metal that is highly valued for being light and at the same time durable. Its density is about one third that of steel, making it ideal for applications requiring components with low weight but high strength.

It stands out, then, for being particularly ductile and easy to work with, so much so that it allows for the creation of extremely complex and richly detailed shapes without sacrificing precision.

THE MOST IMPORTANT CHARACTERISTICS OF ALUMINIUM THAT MAKE IT PERFECT FOR THE MECHANICAL INDUSTRY

The mechanical industry relies heavily on the use of aluminium. This choice derives from some of the main characteristics of this material. The first is corrosion resistance. In fact, this metal alloy naturally forms an oxide layer on its surface. This layer protects against the corrosive action of oxygen and moisture.

Its high strength makes aluminium the perfect material for applications in hostile environments such as mechanical ones where chemicals may be present. Moreover, it is very popular for making those components that are constantly exposed to the elements.

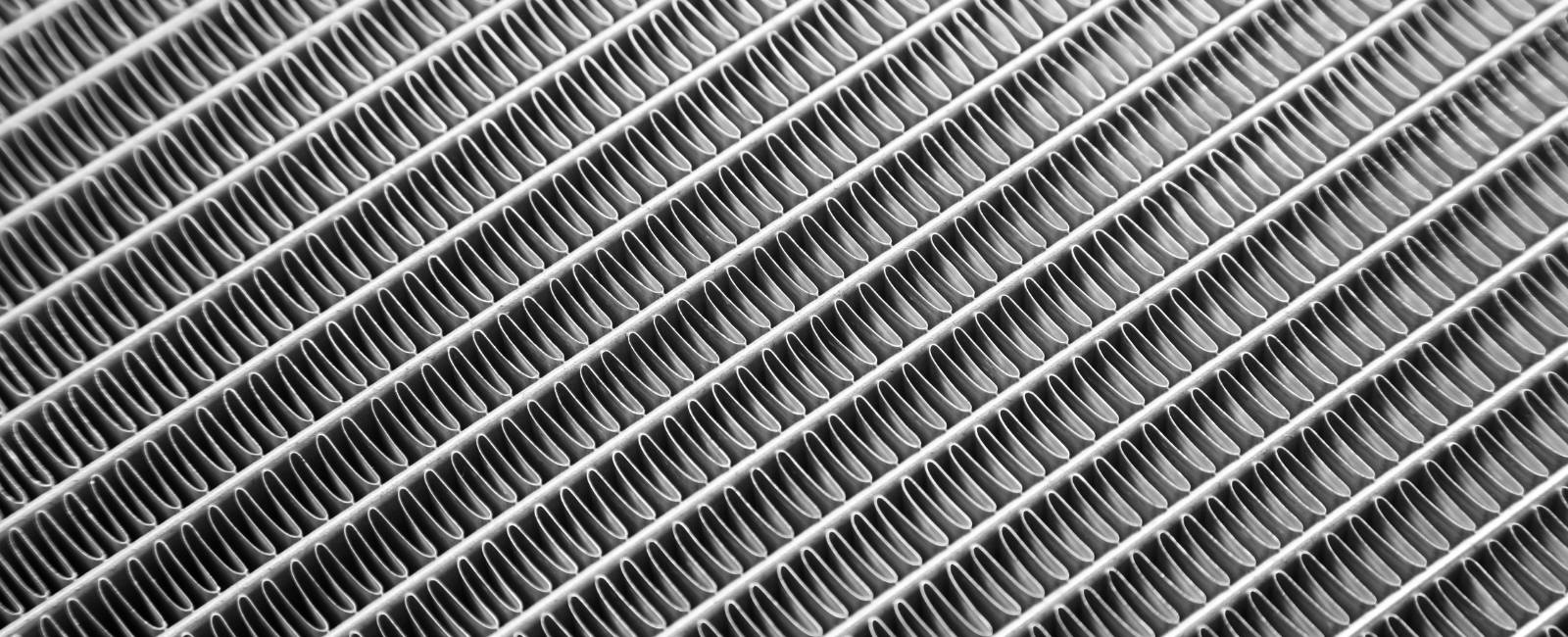

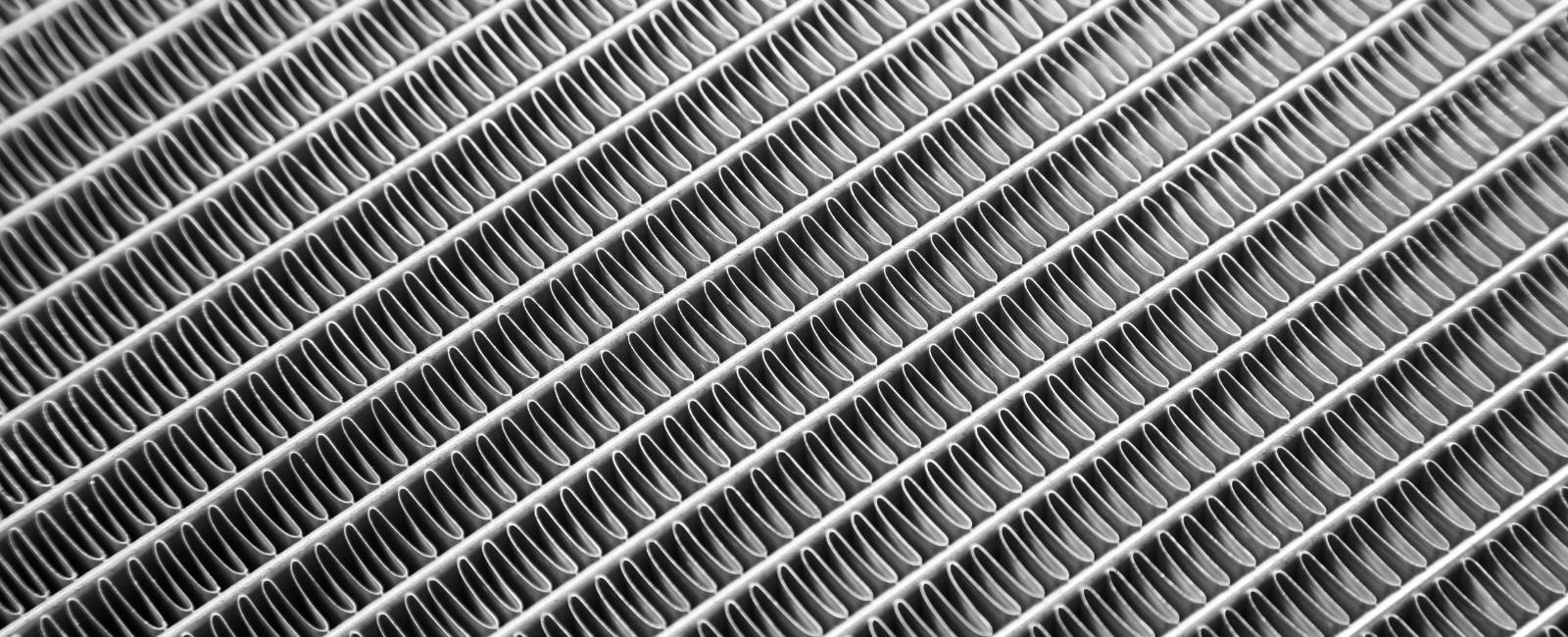

Aluminium is also in great demand for its thermal and electrical conductivity. It is a conductive metal that is ideal for those areas where electricity or heat needs to be transferred. It is widely used for the production of radiators, heat sinks and various electrical components such as connectors and cables.

This high level of thermal conductivity is highly valued in the automotive sector, where aluminium is most often used to create engines and other components that require fast heat dissipation.

Finally, in an area such as mechanical industry nowadays, one cannot help but try to go for environmental sustainability. Using aluminium as the primary material allows you to respect the environment and make an environmentally sustainable choice. In fact, this metal is 100% recyclable and this process requires little energy (much less than the production of virgin aluminium). These steps can be repeated several times without compromising the quality and characteristics of the material.

This means that aluminium is the most sustainable and environmentally friendly choice currently on the market for the mechanical industry, which can thus help reduce its environmental impact.

WHAT ARE THE APPLICATIONS OF ALUMINIUM IN MECHANICS?

Aluminium is fundamental in various applications in the field of mechanics. This is due to its exceptional properties and extreme versatility.

One of the sectors in which this metal alloy is widely used is aeronautics, where it is used to produce structural components, aircraft interiors or coatings. Extreme lightness and corrosion resistance are elements that make aluminium perfect for lowering the total weight of aircraft and increasing their performance in flight.

Another field in which this material is in great demand, as already mentioned, is automotive, where it is used to make bodies, chassis, engines and suspensions. Here too, the limited weight helps to improve vehicle efficiency and limit fuel consumption, while its durability ensures a long service life.

Furthermore aluminium also finds a place in more specific applications such as the railway, shipbuilding or industrial machinery sectors. This shows that it is a raw material that has totally revolutionised the field of mechanics and contributed to its enormous development and innovation.