Discover aluminium surfaces

Aluminum finishing is a fundamental process on the surface of the metal, aimed at optimizing the aesthetic and technical properties of this extraordinary, versatile, and cost-effective material. It is used in various industrial sectors: transportation, construction, mechanics, and electrical engineering, and even in the aerospace industry. Aluminum is increasingly establishing itself in the global market. In this article, we will explore what an aluminum surface finish is, why to choose it over other elements, and the main types. An interesting and necessary deep dive into discovering the processing of this metal with its unique qualities.What is a milled aluminium finish?

Aluminum surface finishing consists of treatments or processes applied to the surface of aluminum to enhance its aesthetic appearance, resistance, and durability. The term finishing refers specifically to the treatment or processing of a material—whether metal, wood, or plastic—or a product, with the aim of optimizing its performance, and these are carried out on its surface. This process gives aluminum specific properties, such as a more uniform finish, corrosion resistance, and the enhancement of mechanical properties, preparing the product for subsequent processing. It is essential, when discussing metal finishes, and in this case aluminum, to make a distinction between coatings and treatments. Coatings are thin layers of material applied to the metal surface to enhance its aesthetic appeal, making it smoother, glossy, or matte, or to improve its corrosion resistance. Treatments, on the other hand, are processes that modify the surface of the metal without adding any coating.Why choose an aluminium finish?

The answer to the question why choose an aluminum surface finish lies in the outstanding qualities of this extraordinary material, which offers both aesthetic and functional advantages. First and foremost, it is the most abundant metal on our planet, and its availability ensures that its cost remains affordable for everyone. More importantly, its specific properties make it a highly malleable and easy-to-process material. For example, after steel, it is the most commonly used metal in the industrial and construction sectors worldwide. However, unlike steel, it boasts a far superior strength-to-weight ratio and exceptional versatility. Aluminum has natural resistance to rust and corrosion, thanks to its ability to form a thin, transparent oxide layer just a few nanometers thick when exposed to air. This makes it particularly suitable for humid or outdoor environments, such as in construction, automotive applications, or industrial machinery. As mentioned earlier, aluminum is extremely lightweight and weather-resistant, standing up to rain, snow, wind, and sun. These qualities make it perfect for various industrial sectors. It is widely used for car bodies and frames, trains, boats, public transport, airplanes, and bicycles—even the Space Shuttle is 90% aluminum. It is also an ideal choice for building facades, windows, and external structures. Aluminum surface finishes can be highly elegant, refined, and modern, offering a wide range of visual effects, from high gloss to matte. Additionally, aluminum can be anodized—an electrochemical process that not only reinforces the surface with an artificial oxide layer for increased durability but also allows for custom colors and unique metallic effects. Furthermore, its ability to adapt to various processing techniques, such as polishing, sandblasting, or painting, makes it possible to achieve a vast selection of textures and finishes. Another clear advantage of this material is its low maintenance requirements. Aluminum surfaces generally require little upkeep, especially when treated with durable finishes like anodization, which significantly extends longevity and reduces the need for frequent cleaning. The last but equally important advantage is its sustainability. Aluminum is an infinitely recyclable material, making it an eco-friendly choice. Recycling requires significantly less energy than its initial production, helping to reduce pollution from raw material processing while also minimizing waste and resource depletion. A metal alloy that is easy to recycle and reuse, this feature makes aluminum a cost-effective and highly popular material.

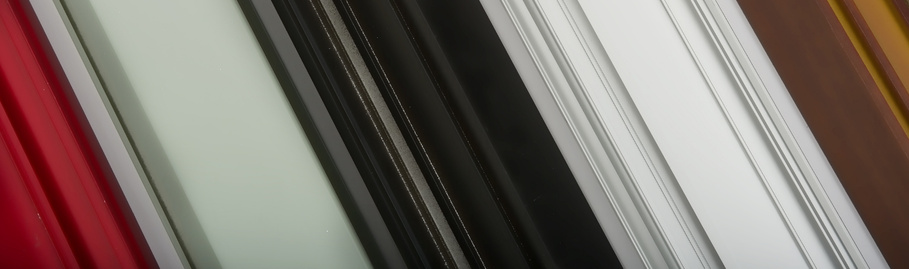

Types of aluminium finishes

There are different surface finishes for aluminum, chemical or mechanical; here are the main types: satin, glossy, polished, dotted, lapped, and brilliant. Satin finishing is a treatment often used in industrial sectors dealing with metal processing, allowing for the uniformization of entire or partial surfaces, giving a predefined, more or less pronounced homogeneous roughness, depending on specific requirements and usage needs. This process employs special brushes or abrasive belts of different types. Polishing is a finish used for both aesthetic and functional purposes, always carried out with special belts or brushes soaked in abrasive paste. This process is the opposite of satin finishing and serves to significantly reduce the roughness of aluminum and metals in general, preparing it for subsequent processing in other industrial fields. Smoothing is a treatment that uniforms and smooths the surface of aluminum, removing surface impurities and achieving a specific roughness. This process is often intermediate, preparing the metal for other treatments. Dotting allows for the uniformization of raw or virgin material, improving both its aesthetic and functional properties. Even in this finish, different results can be obtained, depending on the type of brush used. Lapping is a high-precision finish that minimizes the roughness of the aluminum surface. Special brushes are always used, utilizing an abrasive powder spread over a metal support, allowing for the creation of homogeneous "mirror-like" surfaces. Brightening, finally, removes opacity and oxidation marks from aluminum, giving it shine. The special brushes used for this finish are soaked in a brightening agent, an acidic detergent capable of effectively removing oxides from surfaces. A finish particularly recommended for aesthetic purposes.Choose Casal Aluminium for your aluminium finish

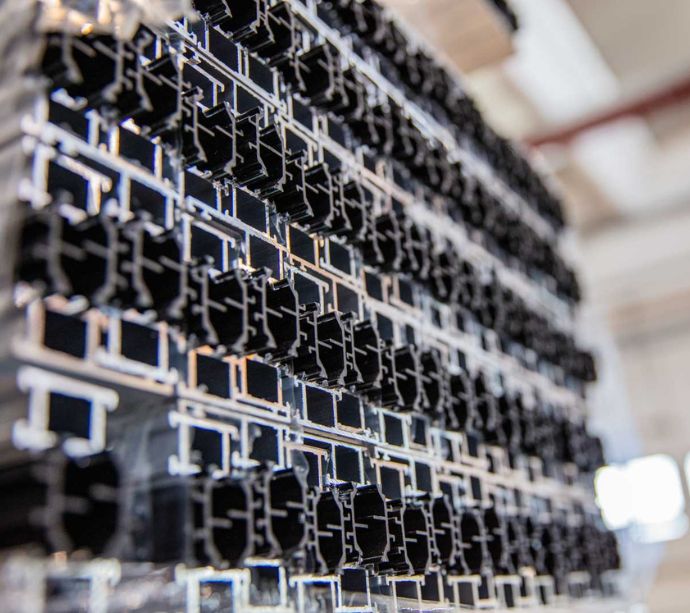

In the national and European landscape, Casal Aluminium certainly represents a reference point in the field of extrusions and surface finishes for aluminum. An innovative company capable of offering a wide range of surface finishes to all our clients, operating in various industrial sectors: construction, furniture, household appliances, transport, mechanics, and much more. This testifies to the importance and the ever-growing demand for aluminum finishes. Turning to Casal Aluminium means relying on the top experts in the sector, with flawless quality and impeccable service. CONTACT US TODAY!

Contact us for more information about the

sale of aluminum profiles.

Would you like a quote or have questions about aluminum profiles?

Contact us via email, phone, or if you prefer, fill out the contact form.

A consultant will get in touch with you in the next few days.

- Casal Aluminium Srl

- Via IV Novembre, 36 26010 Casale Cremasco (Cremona)

- Tel.+39 0373458005

- Mail:[email protected]