A Complete Guide to the Aluminium Extrusion Process

Aluminium is a metal naturally found on the surface of our planet, and after steel, it is the most widely used metal in industrial and construction sectors. Compared to steel, however, it boasts a much better strength-to-weight ratio and has a range of characteristics that make it an extremely versatile material. It is corrosion-resistant, an excellent conductor of electricity and heat, non-toxic, infinitely recyclable, ductile, shock and sound absorbent, impermeable, and can be manufactured into various shapes and thicknesses. The aluminium extrusion process is used to create profiles of specific shapes, sizes, and properties.What is Aluminium Extrusion: Meaning and Definition

But what exactly is aluminium extrusion? To understand this, we must start with the definition: extrusion refers to the industrial production process that uses plastic deformation to create pieces with a constant cross-section. This process can be applied to materials with high plasticity, such as plastics like rubber or metallic materials like copper, steel, lead, and, of course, aluminium. The aluminium extrusion process goes through several phases, which we will discuss in more detail later. Aluminium is a material with excellent plastic characteristics, but it must be heated to a specific temperature for processing. The first phase of the process involves placing the raw material in special furnaces, allowing it to reach a semi-molten, pasty state. At this point, the aluminium is compressed through a die, which shapes the piece being produced. The shaping action on the aluminium occurs via the extruder. This machine consists of a steel cylinder housing one (in the case of a single-screw extruder) or two (in twin-screw extruders) endless screws. The screws have a central core and a spiral-shaped external thread; their main function is to transport the material within the extruder. The cylinder has a feeding zone with a hopper and an exit zone where the die is located. Once inside the extruder, the aluminium undergoes various mechanical and thermal cycles: in the feeding zone, the material experiences minimal pressure changes, while in the compression zone, a significant pressure increase occurs due to the widening of the screw core. In the dosing zone, near the die, the aluminium experiences negligible pressure variations.Aluminium Extrusion: Applications

After understanding the meaning of aluminium extrusion, it’s important to recognize its various applications. As previously mentioned, aluminium is one of the most widely used materials, especially extruded aluminium. One major industry that uses it extensively is the automotive sector, where its strength and lightness make it ideal for producing bodywork, frames, and engine parts. The aerospace industry also frequently uses extruded aluminium for both internal components and structural elements like wings and fuselages. The construction industry is another major sector that uses this metal. Its thermal and acoustic insulation properties make it ideal for roofing systems, but its possible applications are vast (windows, doors, and so on). Aluminium’s excellent thermal conductivity is utilized in appliances and heating systems, as well as in the solar industry. Other sectors that use extruded profiles include lighting, robotics, furniture, design, mechanical engineering, and electromechanical fields.

The Aluminium Extrusion Process: How It Works

The industrial aluminium extrusion process can be broken down into several stages. It all begins with the transformation of the raw material into billets, which are large cylinders measuring 5-7 meters long and 10 inches thick. The billet is placed into a furnace that reaches high temperatures, reducing the metal’s resistance to deformation and making it more malleable. Once removed from the furnace, the billet is prepared for the compression phase. Depending on the machine used and the final product’s dimensions, the billet is cut and placed inside the horizontal press. The press’s job is to compress the now pasty metal, forcing it through the die. After this step, the extruded profile is cooled through several stages, allowing it to gradually regain rigidity while maintaining its desired shape. Before it fully cools, the material undergoes an initial cut. Once cooled and resized, the extruded profile is shaped and straightened through the mechanical stretching phase. Following routine inspections, the semi-finished product undergoes the final cut and is then subjected to a heat treatment in artificial aging ovens. This process strengthens the aluminium’s mechanical properties, making it even more durable and compact. These few lines help explain that the aluminium extrusion process is highly complex, requiring technical expertise, experience, state-of-the-art machinery, and advanced design tools.What is the Extrusion Temperature of Aluminium?

The aluminium extrusion process can be performed at both cold and hot temperatures. In cold extrusion (which still generates heat dissipated via a cooling circuit in the mold), extrusion is driven solely by pressure, applied at controlled speeds and temperatures. Essentially, a punch pushes the billet, which is compressed against the die. This option is mainly used to create pressure vessels like cylinders, bottles, or fire extinguishers. In hot extrusion, the metal is worked at high temperatures to produce semi-finished products of various shapes, both simple and complex, with excellent mechanical properties and functionality. The raw material passes through the mold: the high temperatures make the metal more malleable, allowing it to take on the shape of the die before being cooled. The furnaces where the aluminium is heated before processing can reach temperatures of 450-500 degrees Celsius. The temperature is determined by the type of aluminium alloy used. Generally, the process employs soft alloys, which are easier to work with and weld. These include the following alloy series:- Series 1000: used primarily in the electromechanical and electrical sectors;

- Series 3000: ideal for use in the automotive industry;

- Series 6000: used mainly for welded structures and mechanically worked components for industrial use.

Casal Aluminium for Aluminium Extrusion

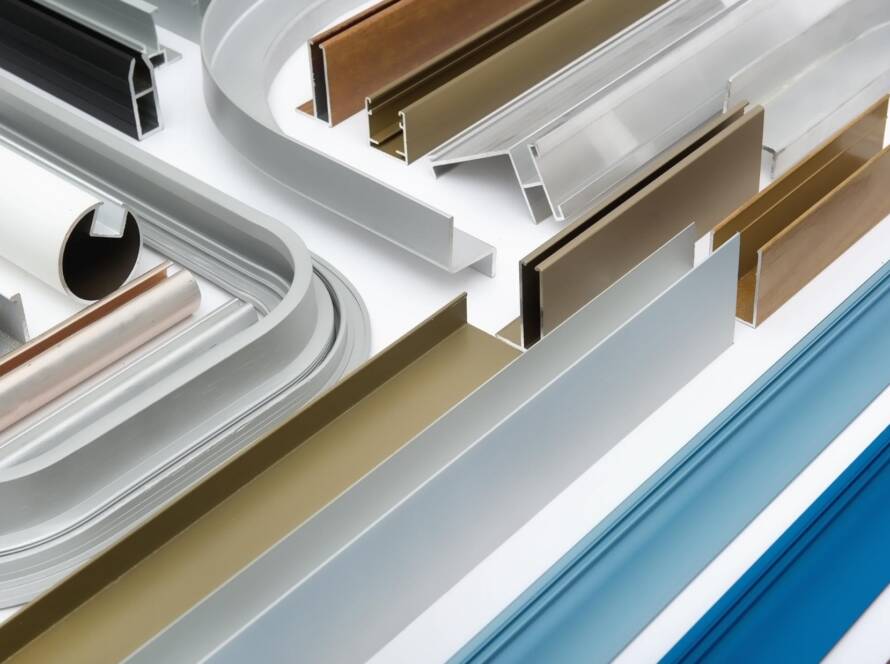

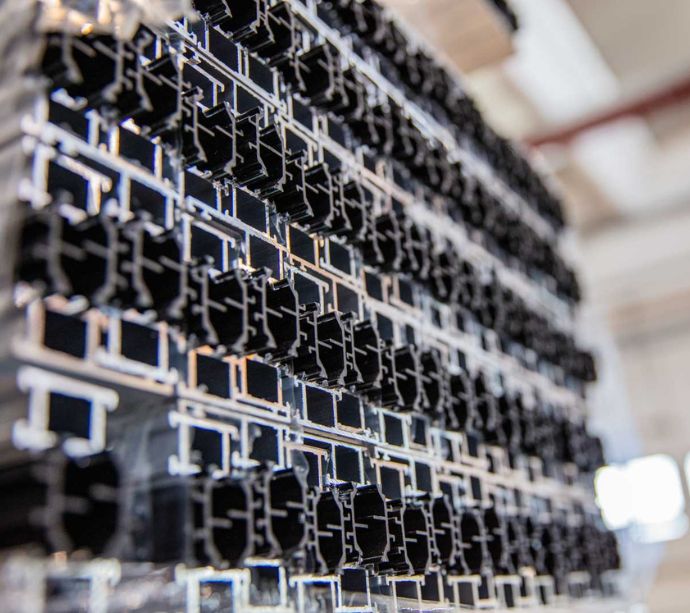

Casal Aluminium is one of the leading national players in the aluminium extrusion industry. Located in Casale Cremasco, in the province of Cremona, this company is composed of top national operators. Their expertise allows them to offer clients custom-designed profiles or standard sections. The list of high-quality aluminium extrusions they provide is extensive:- Custom-designed profiles

- Round bars

- Rectangular bars

- Square bars

- Extruded tubes

- Drawn tubes

- Surface finishes like oxidation, painting, micro-blasting, screen printing, and film coating of extruded aluminium profiles

- Mechanical processing to create products with specific shapes, surfaces, and dimensions

- Profile rolling to shape the metal into decorative and structural elements

- Mechanical testing to precisely evaluate the material’s physical and mechanical properties

Contact us for more information about the

sale of aluminum profiles.

Would you like a quote or have questions about aluminum profiles?

Contact us via email, phone, or if you prefer, fill out the contact form.

A consultant will get in touch with you in the next few days.

- Casal Aluminium Srl

- Via IV Novembre, 36 26010 Casale Cremasco (Cremona)

- Tel.+39 0373458005

- Mail:[email protected]