EVERYTHING YOU NEED TO KNOW ABOUT ANTICORODAL ALUMINUM

Aluminum is an incredibly versatile material used in various industries and beyond. Its success lies in its remarkable mechanical properties: it is lightweight and ductile, yet also highly durable. Perhaps not everyone knows that several alloy variants of aluminum are available on the market, including Anticorodal alloys. Let’s explore the properties of Anticorodal aluminum, the alloys that fall under this definition, the potential applications, and the price per kg.WHAT IS ANTICORODAL ALUMINUM: MEANING AND DEFINITION

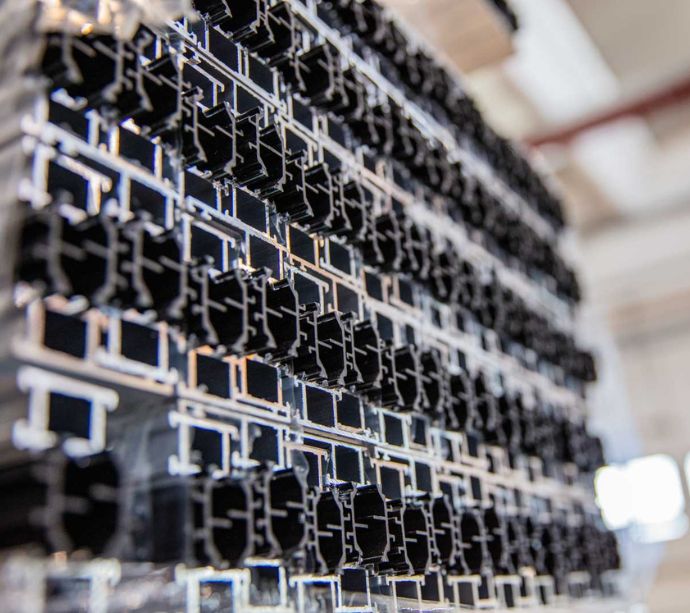

The term Anticorodal aluminum refers to a series of alloys composed of aluminum and percentages of magnesium (between 0.4% and 1.7%), manganese (between 0.5% and 1%), and silicon (1.5%). These alloys are characterized by their excellent mechanical properties and outstanding corrosion resistance; they are also easy to form, machine, cut, and weld, making them useful in various applications. Anticorodal aluminum alloys are heat-treatable (also known as tempered alloys): this means they are first plastically deformed at high temperatures and then subjected to a heat treatment (also known as low-temperature aging), which increases their mechanical strength.ALLOYS AND PROPERTIES OF ANTICORODAL ALUMINUM

As previously mentioned, the term Anticorodal aluminum does not refer to a single type of metal but to a range of alloys that contain the same elements and are marked by high resistance and performance, though there are significant differences between them. Let's take a closer look at each.ANTICORODAL 6082

This is probably the best-known Anticorodal aluminum alloy, often referred to as a structural aluminum alloy. It’s not hard to see why it has this nickname: it is a very strong alloy with particularly high corrosion resistance, thanks to the stability provided by its high manganese content. However, it is one of the more complex alloys to process, especially when manufacturing intricate shapes through the extrusion process. Specifically, in addition to aluminum, the alloy contains:- Silicon (0.70% - 1.30%)

- Iron (up to 0.50%)

- Copper (up to 0.10%)

- Manganese (0.40% - 1.00%)

- Magnesium (0.60% - 1.20%)

- Chromium (up to 0.25%)

- Zinc (up to 0.20%)

- Titanium (up to 0.10%)

ANTICORODAL 6060

Compared to Anticorodal 6082, this alloy offers excellent extrudability, allowing it to be used to manufacture very complex profiles. However, despite having very good corrosion resistance, it doesn’t offer high strength. Along with aluminum, the alloy contains:- Silicon (0.30% - 0.60%)

- Iron (0.10% - 0.30%)

- Copper (up to 0.10%)

- Manganese (up to 0.10%)

- Magnesium (0.35% - 0.60%)

- Chromium (up to 0.05%)

- Zinc (up to 0.15%)

- Titanium (up to 0.10%)

USES OF ANTICORODAL ALUMINUM

Anticorodal aluminum alloys are incredibly versatile and can be used in a variety of fields. They range from window frame production and outdoor antennas to the creation of frames for motorcycles and bicycles, architectural applications, technical furniture, and welded structures in general. Since the various alloys of this type have specific properties, each one is better suited for particular applications. Anticorodal 6082 aluminum is used in sheets, pipes, bars, plates, and various profiles. Its corrosion resistance, the possibility of obtaining solid welds, and adequate machinability make it the perfect material for the automotive sector, railway construction projects, as well as architectural elements and structural parts (such as bridges and beams) where high standards of corrosion resistance are required. Anticorodal 6082 is also used to manufacture various machine parts and containers like beer kegs or clamps. Anticorodal 6060 aluminum, as mentioned, retains good corrosion resistance but has lower strength. It is, however, easier to machine and allows for the production of even complex profiles. Therefore, it is used not only in the form of round, flat, and Anticorodal aluminum tubes but also as custom-made profiles. Typical applications include the manufacture of structural elements that require high corrosion resistance but not high strength, architectural details, pipes for irrigation and air conditioning, and the creation of profiles with composite cross-sections.PRICE PER KG OF ANTICORODAL ALUMINUM

It’s never easy to get a precise idea of the cost of certain products. Therefore, it's difficult to say with certainty how much Anticorodal aluminum costs per kg: many variables come into play, from the raw material price to the chosen alloy type, the quality, the type of product required, and the processing involved. It is best to contact the staff at Casal Aluminium to request information and get a quote. A form is available on their official website for sending inquiries, and other contact methods are also provided, such as the phone number +39 0373 458005 and the email address [email protected].BUY OUR ANTICORODAL ALUMINUM

But why buy Anticorodal aluminum from Casal Aluminium? Primarily due to the vast range of products (custom profiles, round, square, and rectangular bars, extruded and drawn tubes) and application diversity (special surface treatments, mechanical processing, profile finishing, mechanical testing) and the quality of the raw materials used. Additionally, they offer efficient and quick consulting and support services, a commitment to environmentally friendly policies, and various certifications that demonstrate the company’s high-quality standards. Casal Aluminium is also the ideal partner for more complex needs, as they can provide the best solutions, even for Anticorodal aluminum products, thanks to their experience, innovative vision, and use of cutting-edge technologies.

Contact us for more information about the

sale of aluminum profiles.

Would you like a quote or have questions about aluminum profiles?

Contact us via email, phone, or if you prefer, fill out the contact form.

A consultant will get in touch with you in the next few days.

- Casal Aluminium Srl

- Via IV Novembre, 36 26010 Casale Cremasco (Cremona)

- Tel.+39 0373458005

- Mail:[email protected]